WurthMachinery.com

During the month of August, we’ll be featuring various companies within the woodworking world and how they make an impact on the industry through innovative products, creative expertise and unparalleled customer experiences. Today, we’re taking an exciting first look at CNC Factory’s Raptor XPR CNC Router and Machine Center, exclusively available for Wurth Machinery customers.

Company: CNC Factory

Years in Business: Established since 2015 by Chris Corrales, an ISO-Certified cabinetmaker of over 20 years. Chris has been making CNC machines for over 15 years, and their technology is based on his decades of experience.

It’s a game-changer.

With the manufacturing industry facing struggles like rising material costs and the skilled labor gap, it goes without saying that times are changing – and with change, comes innovation.

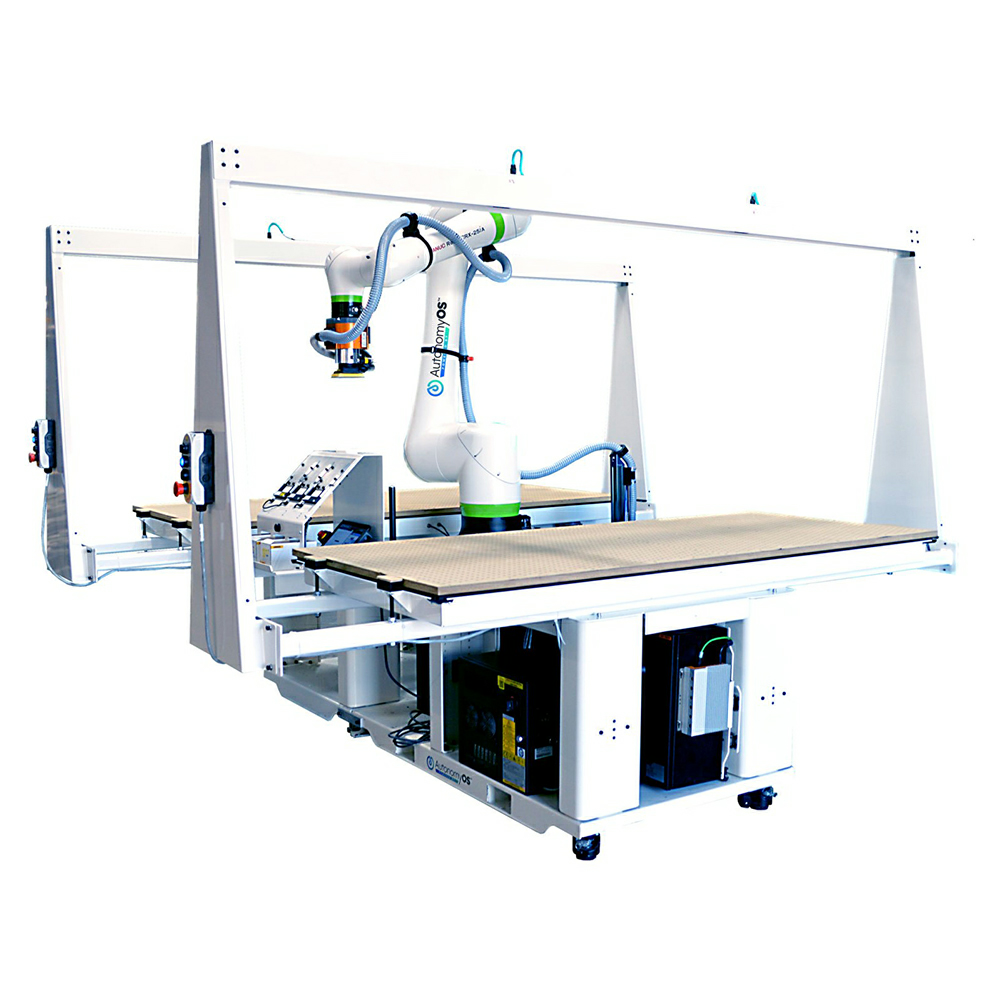

Enter the Wurth exclusive, CNC Factory’s Raptor XPR CNC Router and Machine Center – the newest and greatest in automated machinery, helping to make even the hardest parts of your day easier (and easily our #1 workshop essential).

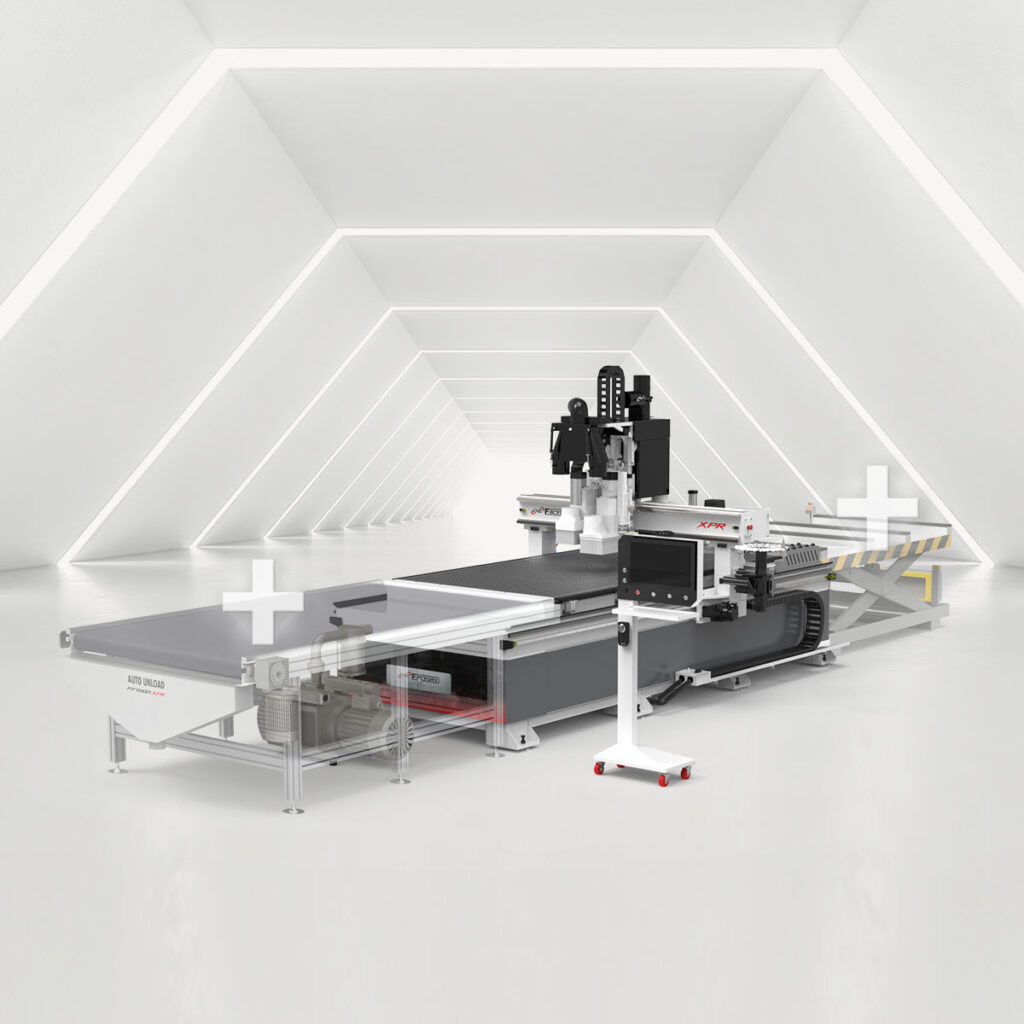

CNC Factory said it best themselves: “The Raptor XPR CNC Router and Machine Center automates the most laborious and mentally complex processes in modern woodworking – eliminating heavy lifting from loading and unloading materials, intricate cutting, parts making and work area cleaning…all without G-code knowledge. Intimidation is no longer a factor since it can be operated with zero experience,” says Jae Santos, Marketing Communications Head for CNC Factory. Plus, its small footprint fits perfectly in even small to medium-sized shops, and can produce the output of up to 8 skilled workers!

It combines cutting-edge technology from all over the world.

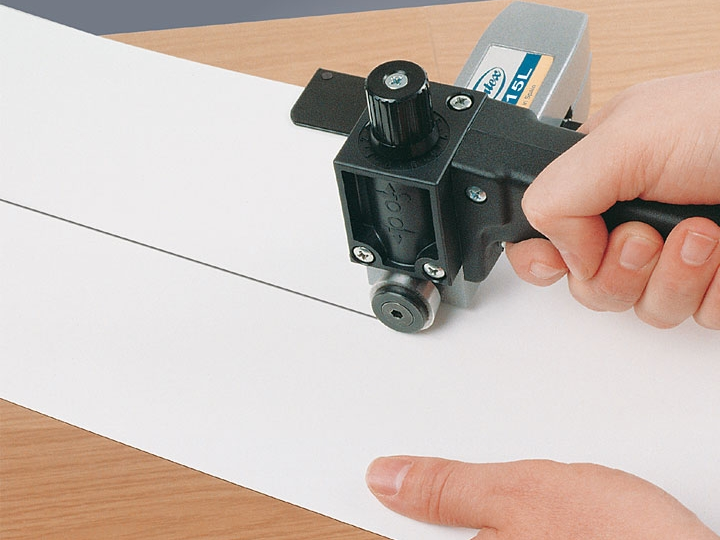

“Designed in California, the Raptor is a true feat of engineering made up of the best technologies from around the world – Germany, Japan, Taiwan, etc. It stands out from competitors by how easy it is to use (with the 21” touchscreen with PC front end so you can design and cut at the machine; it has a visual interface, automatic vacuum controls, and no homing), and by our personalized customer service program (we even have an Advanced Exchange Program where we ship you your replacement parts even before you send the old parts back to us),” Jae continued. In regards to productivity, Raptor users can expect to process about 100 sheets during one 8-hour shift.

Bottlenecks in workflow are reduced at literally every stage of the process, from material loading to cutting, marking and unloading flow constantly – without the need for breaks or human intervention. It’s easy to use: operators need only adjust a few settings, and multiple jobs will queue automatically – saving your business time, and giving back the ability to focus on the more important tasks at hand. For safety reasons, CNC Factory recommends that one operator is always close by, however they can easily multi-task and work on other projects while they wait for the Raptor to work its magic.

It can be operated remotely.

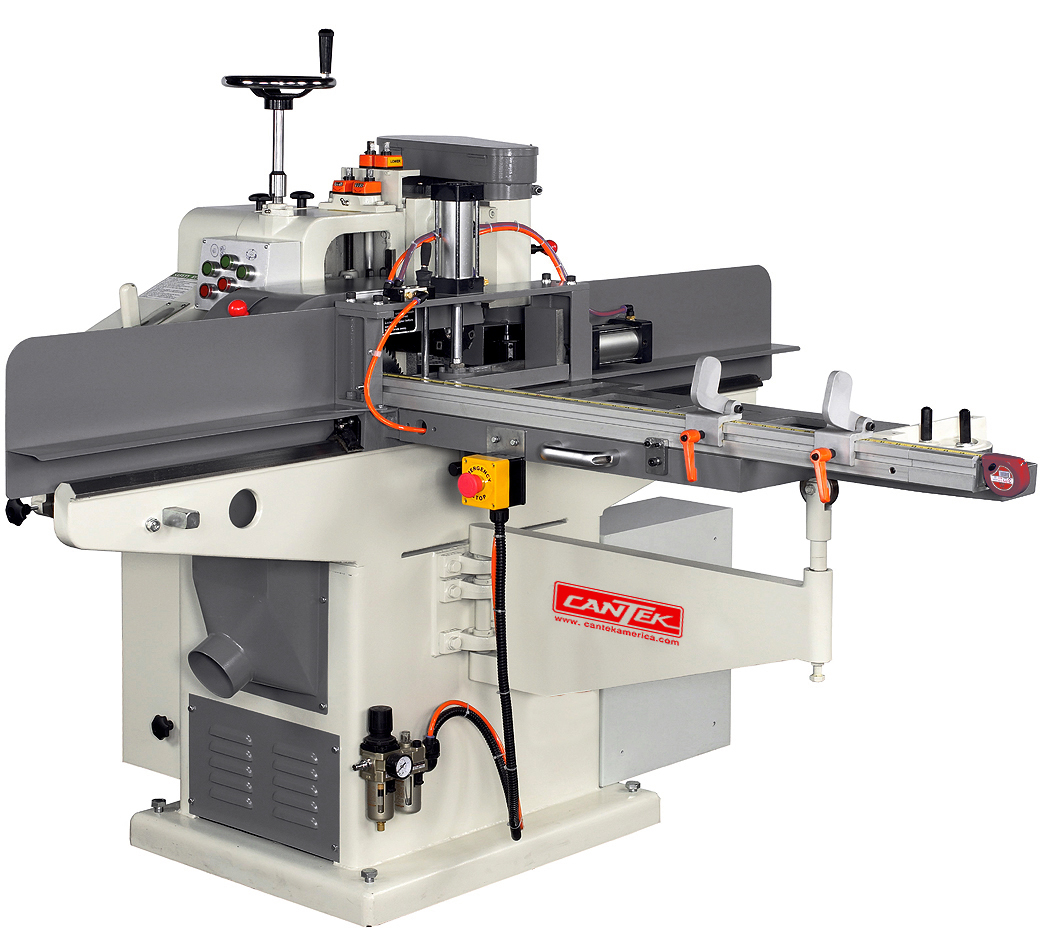

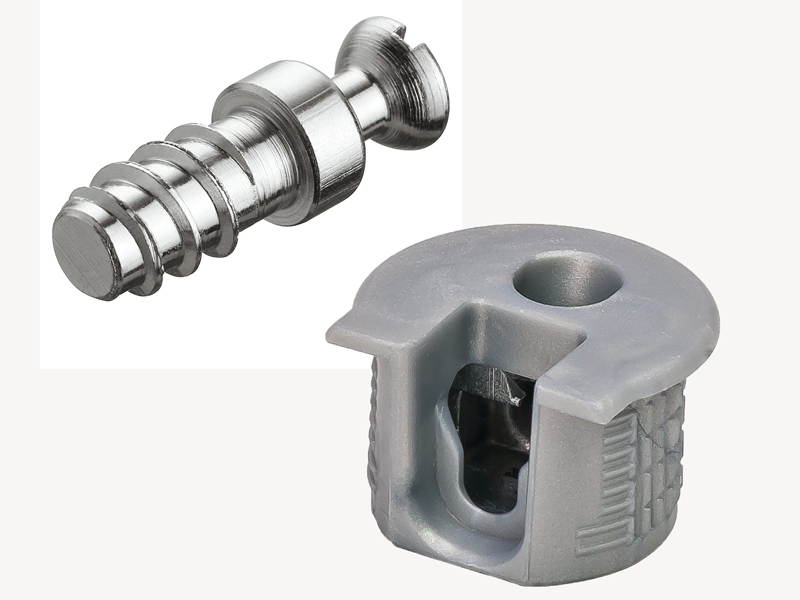

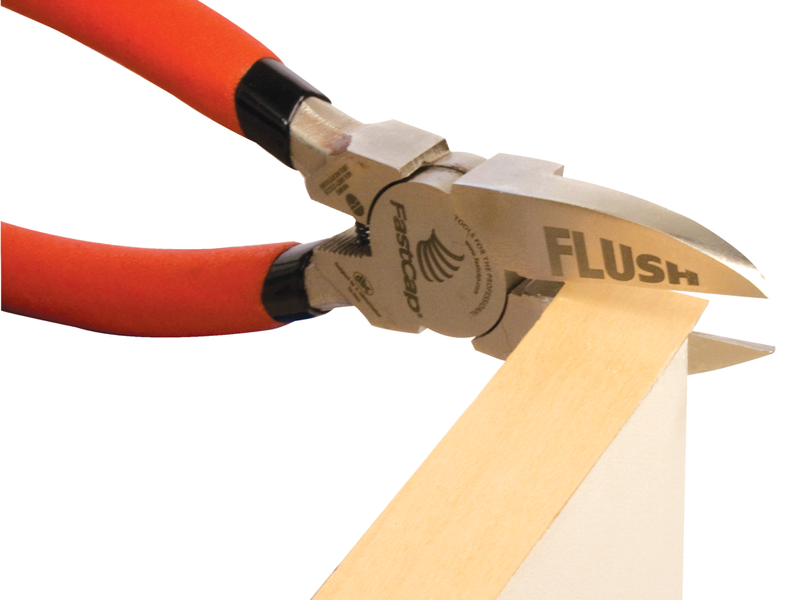

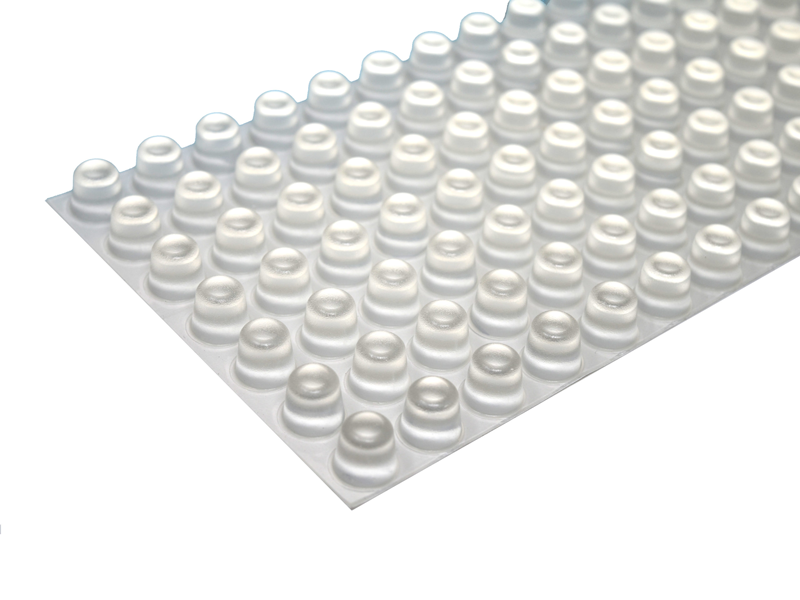

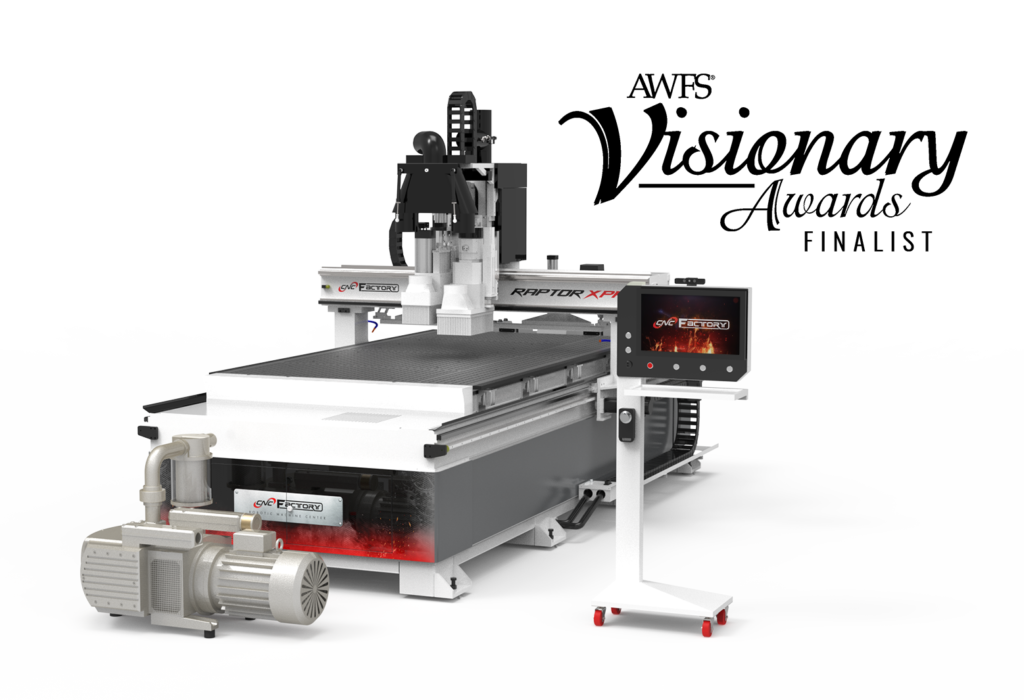

Even more exciting? It can even be monitored remotely. This gives managers more freedom, and allows CNC Factory to help troubleshoot any issues by their technical support team without having to call in and wait for a mechanic. Sound too good to be true? What’s more – it’s affordable! The Raptor rivals competitors with its cutting edge technology from all over the world, and is still available at a lower price point than many other CNC routers out there. “The features and expandability of the Raptor rivals competitors with double the price point. Also, the Raptor is Working Cell-ready, which means it is compatible with our edgebander, CNC Insertion, and conveyor products which can all be manned by a single operator. And don’t just take our word for it, our XPR series has also been named Best CNC of 2020 by FDMC Magazine.”

Check out the Wurth Raptor XPR CNC Router in action:

Excited to learn more? CNC Factory invites all Wurth customers to see the XPR in action at the AWFS Fair. Let their team know that Wurth sent you for reduced pricing and an extended warranty! Get free admission to the AWFS Fair in Vegas with CNC Factory’s exhibitor code:

Warranty Info:

CNC Factory: “The Wurth Raptor XPR has the longest CNC warranty in the industry of 20 months. All Raptors also come with a 5-year Advanced Exchange for parts, and lifetime customer support. Our support can be done virtually (the machines have an HD camera & Wi-Fi connectivity so we can see, operate and assist your operator in real-time throughout North America) from our tech centers in the East and West Coast.”

Client Testimonials:

Have more questions? Contact a Wurth Machinery specialist today at (800) 422-4389.