WurthMachinery.com

During the month of August, we’ll be featuring various companies within the woodworking world and how they make an impact on the industry through innovative products, creative expertise and unparalleled customer experiences. Today we address a major issue in the manufacturing industry: the skilled labor gap. If your business has been impacted by this crisis, Superfici can help.

Company: Superfici America

Years in Business: Started in Northern Italy since the 1980’s, American headquarters since 2005

With rising material costs, supply chain shortages and a skilled labor gap, the landscape of the manufacturing industry over the course of the last year has changed substantially. Up to 82% of U.S.-based manufacturers alone face a significant shortage in skilled workers, leading to production issues and greater problems down the road.

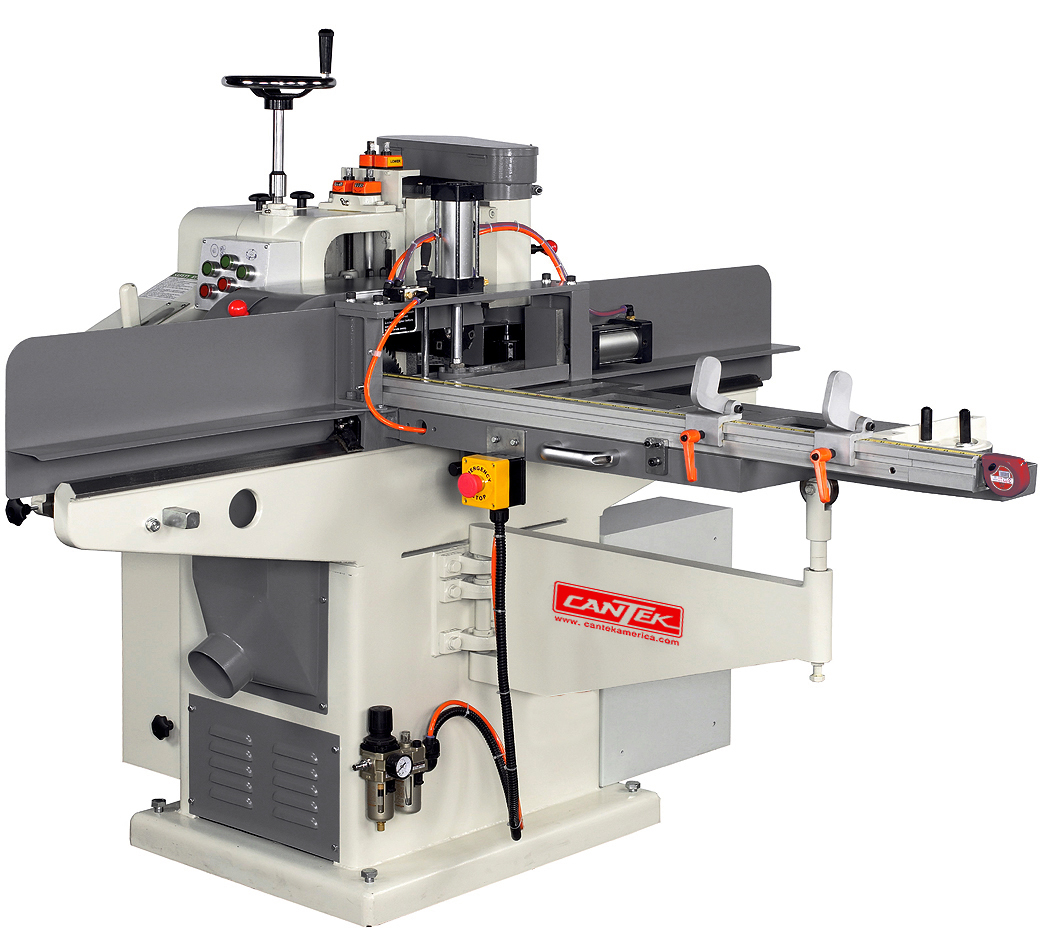

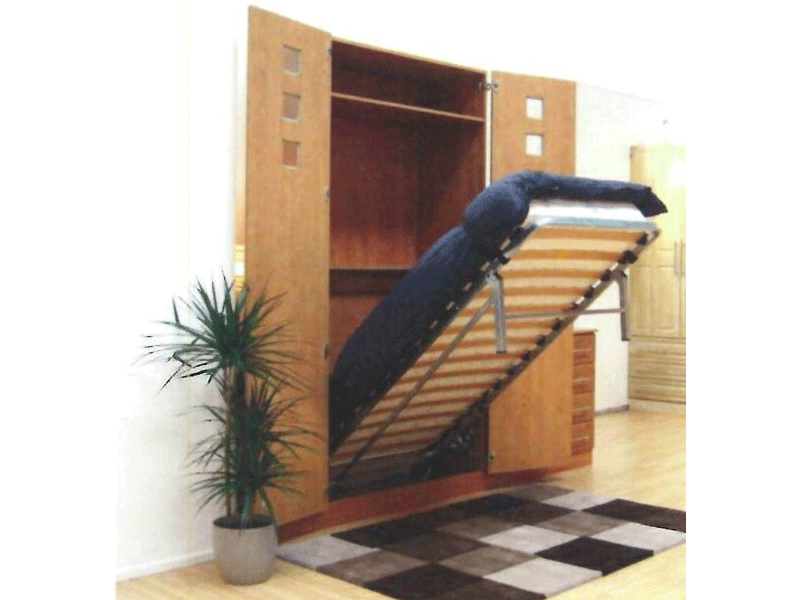

In light of this, Superfici has come up with a solution to help address the ever-changing situation of the manufacturing industry. An Italian-based company, Superfici has served for decades as a market-leading supplier of complete industrial finishing systems, recognized around the world for their premiere product range of automated solutions. Throughout the years, their mission has remained steadfast, expanding their expertise to include the production of coating systems for glass, plastic, graphic arts, metals and composite materials – and more importantly, they are committed to helping businesses like yours thrive by taking them to the next level.

Here’s what Superfici’s robotic solutions can do for your workshop:

- Replace the need to find reliable labor, which is hard to come by in today’s market

- Increased production capacity compared to hand spraying

- No more painter burnout

- 100% Consistency – Outputs perfectly finished product, every time

- Get back up to speed – start competing with larger workshops with automated machinery and meet market demand

- Convenient Size – Superfici’s Mini Plus automated sprayer fits in small spaces

- Cost savings on labor

- Time – prioritize more important projects while the Superfici Mini Plus gets the job done for you

- Easy to learn – anybody with basic smartphone or computer skills can learn to operate the Superfici Mini within mere minutes

- Amazing customer service and training resources after purchase

- Highly-customizable solutions to accommodate each individual client’s needs – it’s not a one-size-fits-all solution

- Easy installation – get up and running same day of delivery

Superfici is on your side when it comes to accommodating client needs, customization and making the automated experience as seamless as possible. “We offer complete turn-key solutions customized to their current and estimated future production needs, and package everything into our installation for them so they do not have to communicate with any other suppliers. We also customize the programming of the machines to match their current workloads and product specifications, so that from day one when our machines are installed, they’re off to the races ready to run – the goal of course is to minimize or eliminate any down time in the transition. We consider everything in the consultation phase – available space, airflow, ventilation, team size, finished feet per minutes/products per day to maximize profitability,” said U.S. division Superfici Marketing Manager, Jeff Henry.

Here’s an idea of how much time the Superfici Mini Plus can really save you:

- Automatic Spray Machine: 5-10 minutes vs. Manual Spraying: 40-45 minutes

- Automatic Spray Machine: Up to 1,000 pieces per day, 2-coat process or 750 per day with a 3 coat process vs.

- Manual Painter: 120 pieces per day with a 2-coat process, or 80 pieces per day with a 3-coat process.

“The impact on our company has been amazing, really. The volume of material we can finish in half a day with the machine is more than we could have done in a full day with four booths running, and the cost savings on labor and adding those booths is significant.”

-Superfici Customer Robert Malandrino, Production Supervisor for Alka Kitchen Cabinets, Weston, Ontario

While you may think that purchasing one of these automated machines is too costly for the size of your workshop, the numbers suggest otherwise. Here’s the breakdown: According to Superfici’s Marketing Manager Jeff Henry, “On average in the USA, a professional manual spraying technician costs about $20 US, or about $150 per day [not including benefits and other job perks]. Contrast that with a Superfici America Mini automated reciprocal spray machine on a 5-year-lease, which runs about $76 per day, and most resistance to automation starts to crumble.”

Still not sure if Superfici’s solution can meet your needs? Here a few questions to help you get started:

- Does your finishing capacity meet your current manufacturing demands?

- Has manually spraying cause any negative impacts to your business (ie, inconsistent quality, slow production, etc)?

- Is every piece 100% consistent and help to the highest standards, each and every time?

- Have you had difficulty finding reliable, talented workers during the skilled labor gap crisis?

- Do you hope to expand your manufacturing capabilities, and your business in general? What business objectives does your workshop have for the next five years?

Ready to learn more? Contact a Wurth Machinery specialist today at (800) 422-4389.