WurthMachinery.com

During the month of August, we’ll be featuring various companies within the woodworking world and how they make an impact on the industry through innovative products, creative expertise and unparalleled customer experiences.

For this article, we’re showcasing tips and tricks from the award-winning “pioneers in wood joining”, Lamello. Their innovative joining systems provide durable and sophisticated solutions for wood processing, shaping the woodworking industry into what it is today. From geometric chairs to designer furniture and impressive outdoor sculptures, we’re going to take a look at a few of the many inspiring pieces that can be made with Lamello’s cutting edge technology.

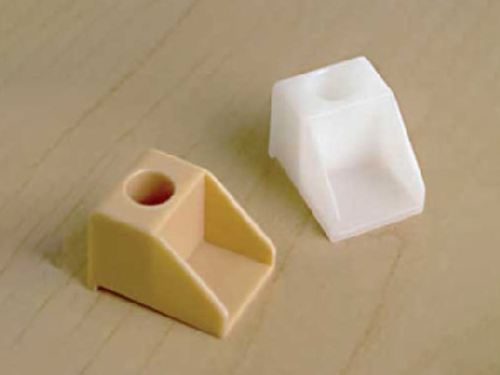

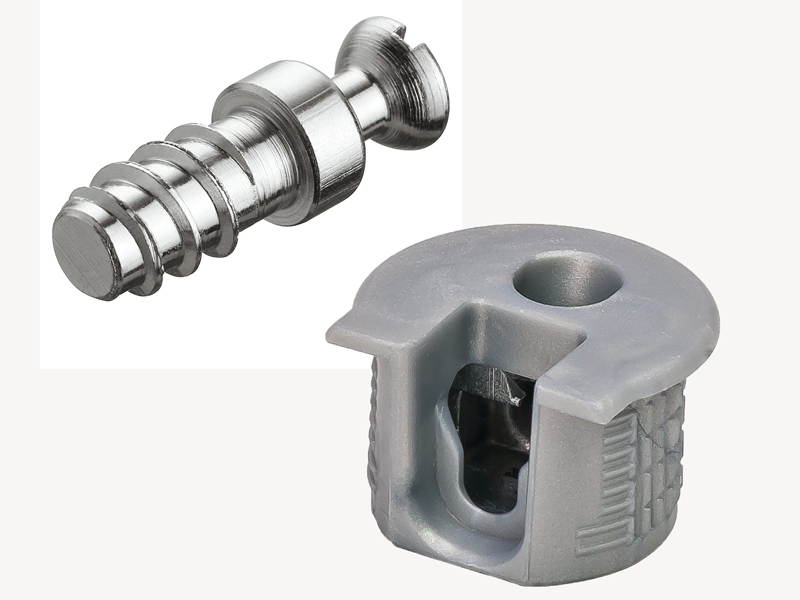

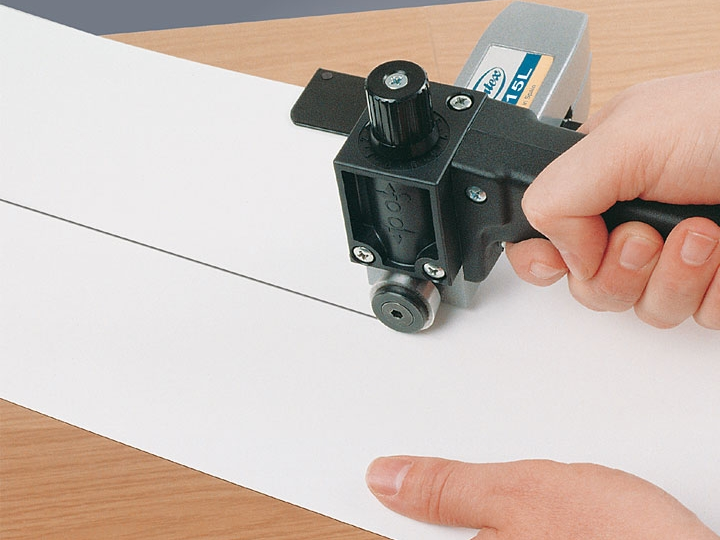

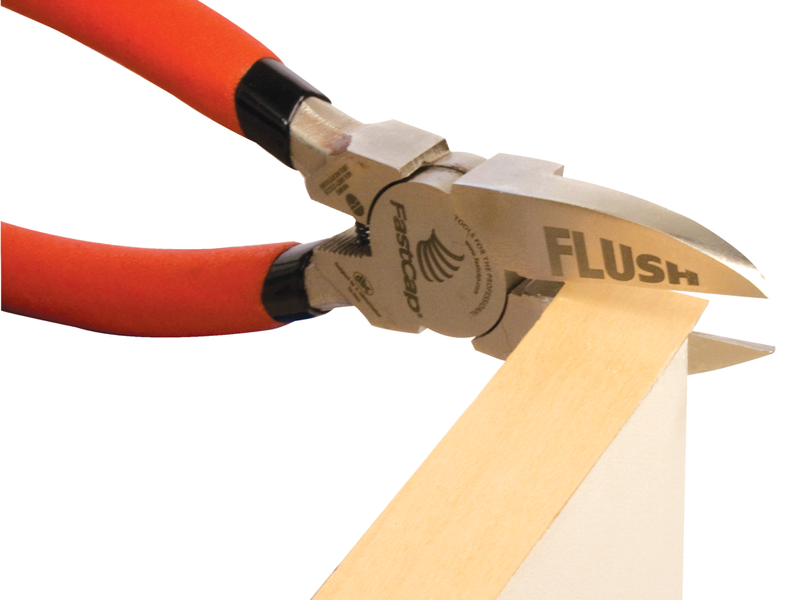

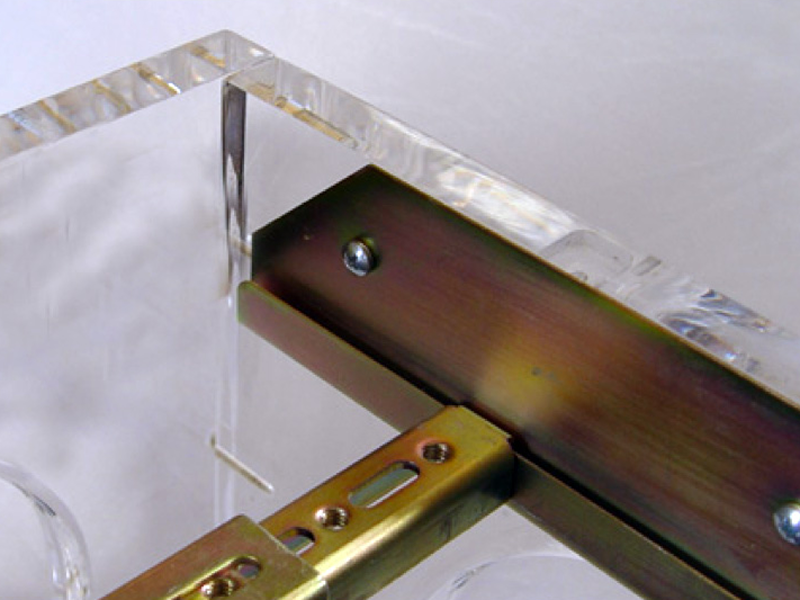

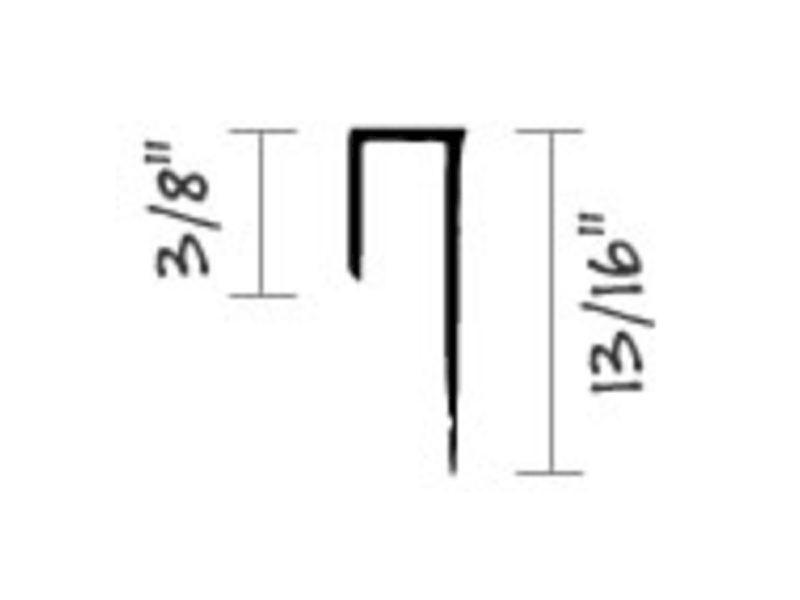

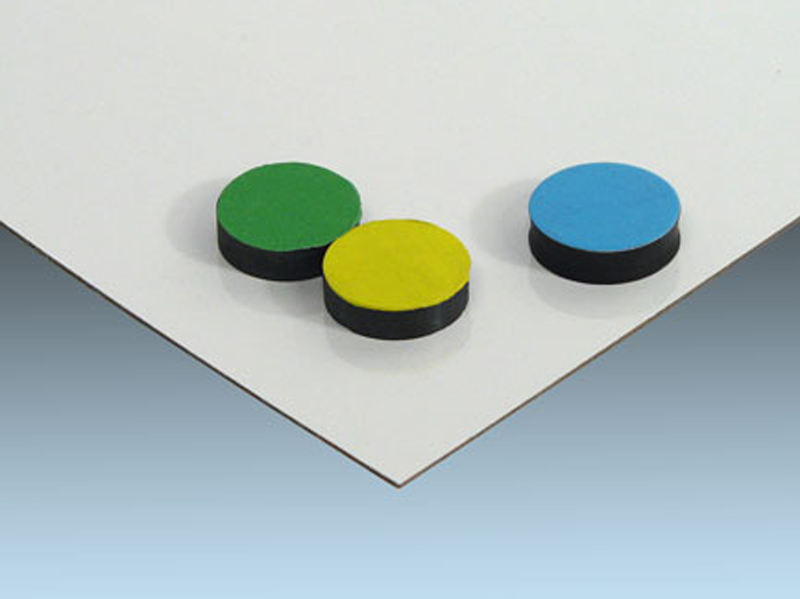

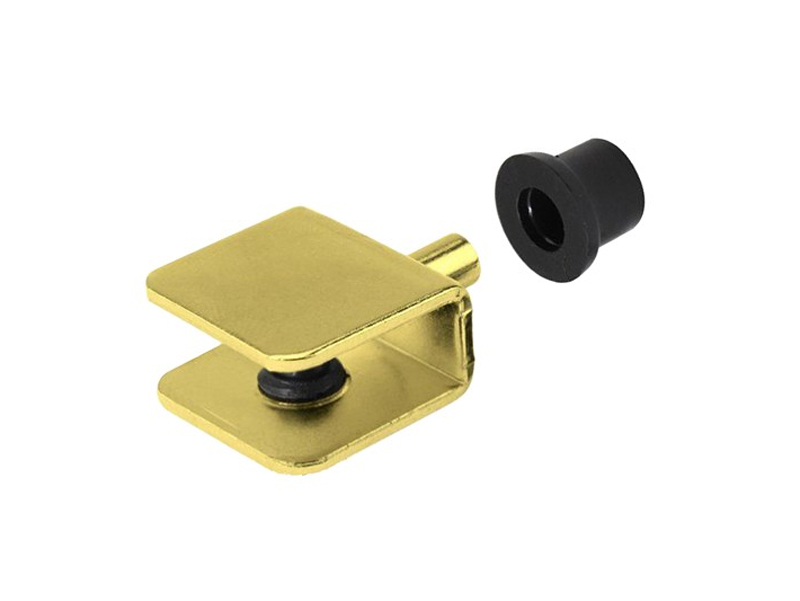

But before we dive into all of your future project #inspo, here’s a quick introduction on Lamello’s P-System: Used in tandem with the Lamello Zeta P2 Biscuit Joiner, wood connectors are a fast and easy way to join wood parts in cabinetry, case goods, carpentry and so much more! Below, we’ll take a look at Lamello’s 3 main types of connectors (Clamex, Tenso and Divario) and how they can be used for various applications and projects – plus, some tips and tricks along the way!

- “The Corner” – Created with the Clamex P-14

An artfully designed retreat away from the hectic bustling of daily activities, “The Corner” seating shell makes the perfect escape for high-traffic areas including lobbies, offices and more. “The Corner” was transported in separate pieces and then easily assembled on location with Lamello’s pre-assembled Clamex P-14 connectors.

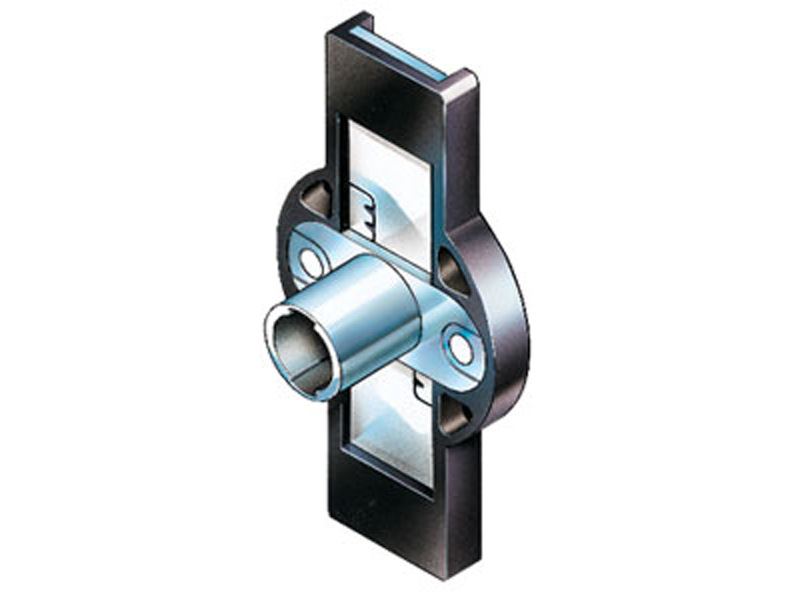

Lamello Pro Tip: “When Clamex P is installed, simply press the parts together and use a hex key to turn the cam lever and engage to the matching half and the parts are joined leaving the Clamex parts invisible. These can be used in cabinet boxes, face frames, and [are] particularly useful [for] joining beveled miter edges.”

2. Designer Furniture – Tenso P-14

Lamello Pro Tip: “Simply make the P System slots with the Zeta biscuit joiner or a CNC machine, slide the Tenso into place, apply glue to the parts and press the parts into place. This will squeeze out any excess glue and hold the parts with 35 pounds force until the glue cures. Once in place, Tenso is totally invisible.”

3. Asymmetrical Shelves – Clamex P-14 & Tenso P-14

For this asymmetrical, whimsical piece, both the Clamex P-14 and Tenso P-14 connectors were key in the design process, enabling streamlined assembly and implementation. Seemingly straightforward, the designer was challenged with slanted shelves, which were made possible with Lamello’s connectors. Used in tandem with the Lamello Zeta P2 System, a creative, asymmetrical structure such as this one can be constructed in no time.

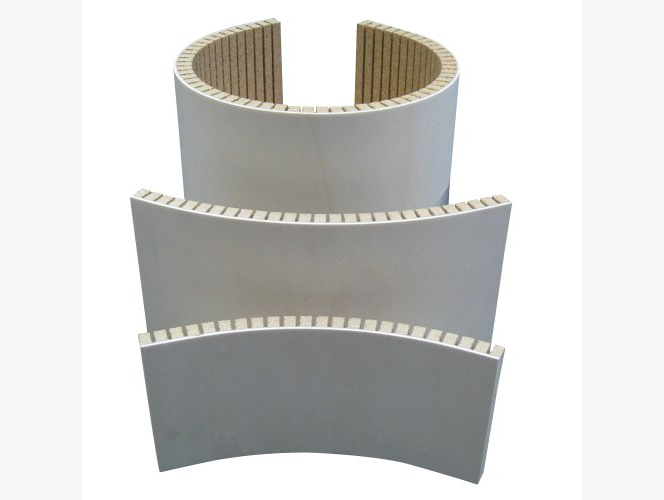

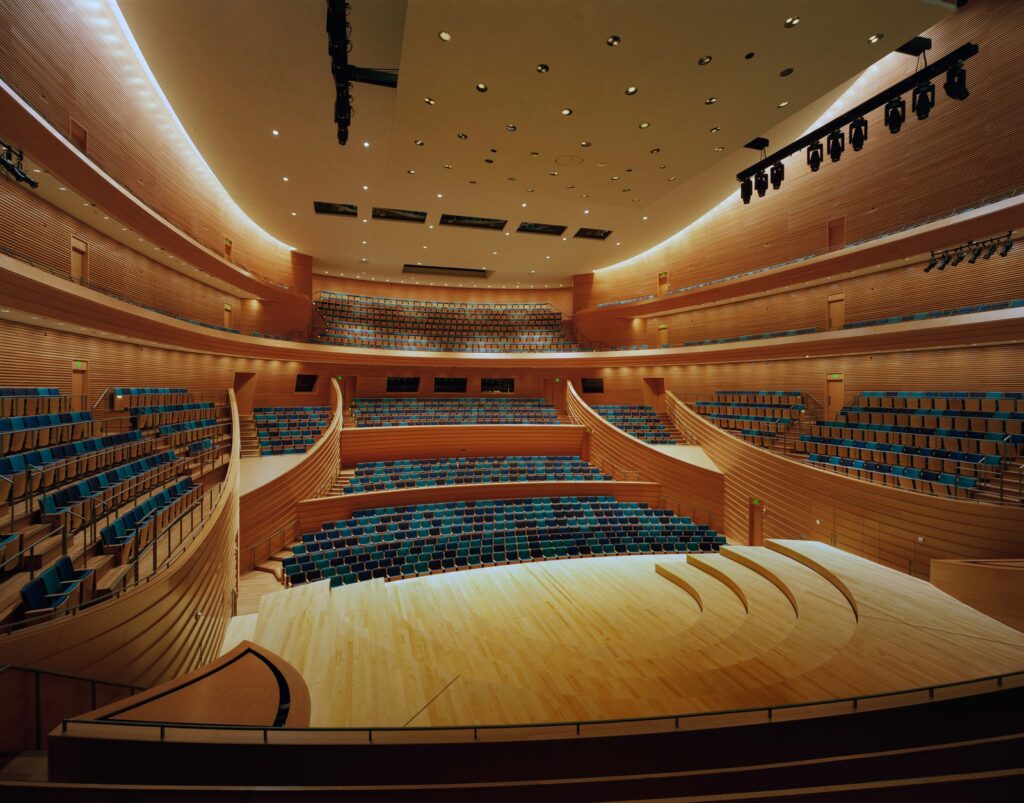

4. “Holz in Form” – Shaped Wood Using the Clamex P-14

Literally translating to “shaped wood” in German, “Holz in Form” is quite the structural feat when it comes to woodworking. With the help of Lamello’s Clamex P-14, 380 square meters of oak veneer and 30 years of expertise – this amazing wooden ball has been created. The carpentry company that created “Holz in Form” has mastered all sorts of creations in various shapes and sizes for furniture using Lamello’s joining systems.

If you weren’t impressed up until this point, you will be now! Even large outdoor structures can be seamlessly put together using the Lamello P-System. Here, an immense structure was created on-site with the Tenso P-14. “The Lamello Tenso connectors allow for the easy and quick assembly and adhesive joining (1K PUR adhesive) of the 200 individually shaped boxes with 1.200 miter joints where all angles were slightly different. This makes it an inexpensive, sustainable and fast construction method for freeform structures, interiors, stage design etc.”

6. Nordic Lighting Unit – P-System

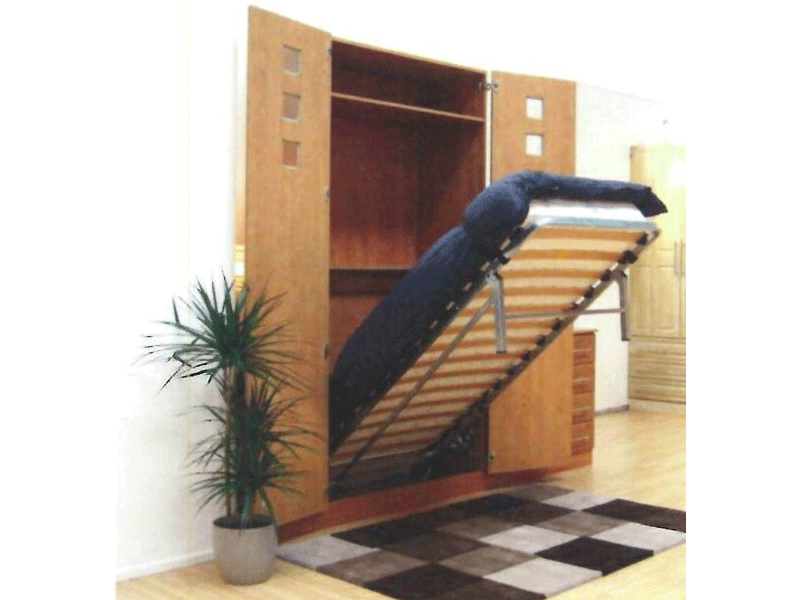

7. The Ultimate Floating Wine Shelf – Divario P-18

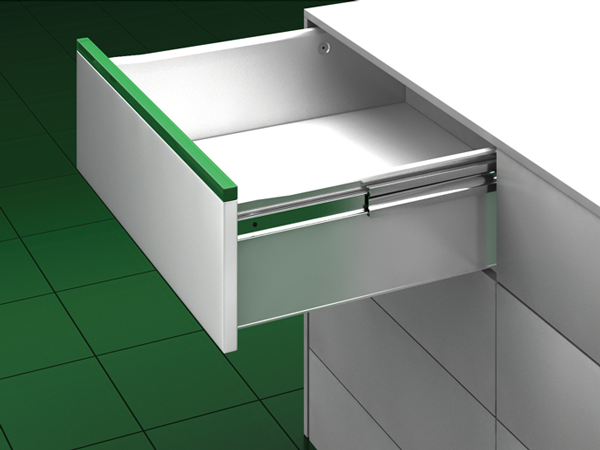

To create a seamless floating shelf like this one, the Divario P-18 connectors are ideal. The connectors won’t be visible, yet still offers the possibility of detaching if necessary. Use the Divario P-18 to create solid sides for the shelves. “Vertical parts have been attached to the rear wall and horizontal shelves have been inserted. The ample tensioning force of Divario P-18 leads to a stable connection throughout the shelving unit.”

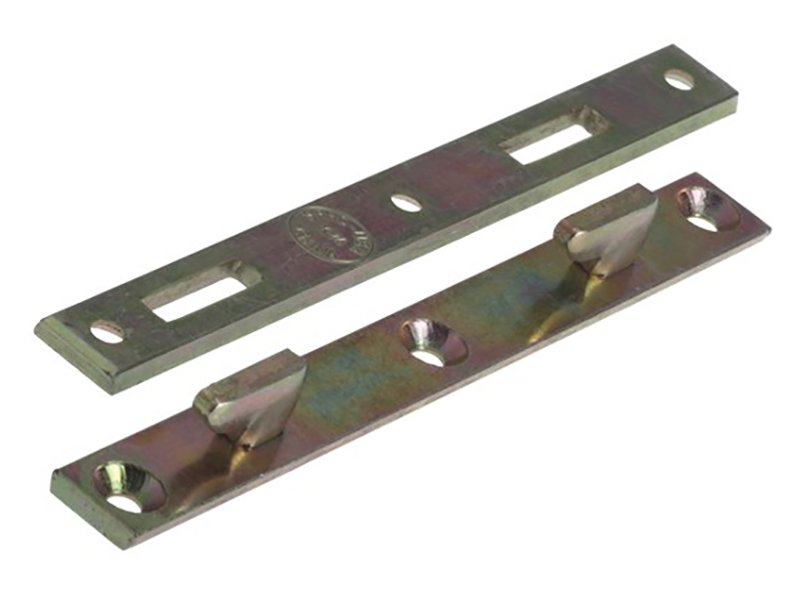

Pro Tip: “The Divario P connector is for horizontal shelves or vertical dividers. It allows for invisible hardware and it also acts as a connector as it draw parts together securely, holding them in place, yet also allows for the parts to be disassembled if necessary.”

Looking for even more inspiration from the wood joining experts? Be sure to check out their Tips and Tricks or their inspiration page! Or, check out some of Lamello’s other interactive resources:

Lamello Zeta P system for wood joining:

Lamello P System connectors: Zeta or CNC Router

Lamello Zeta P2 Best Practices

Overview of Lamello P System Connectors and Zeta Biscuit Joiner

Attaching Face Frames with Lamello Tenso Connectors

Lamello USA Instagram:

https://www.instagram.com/lamello_usa/

Have you made any projects using the Lamello P-System, or do you have tips and tricks to share with our community? Share a photo with your work on social media and tag @WurthMachinery for a chance to get featured on our channel!

To place an order or ask a question about our selection of Lamello products, please contact a Wurth Machinery specialist at (800) 422-4389.