During the month of August, we’ll be featuring various companies within the woodworking world and how they make an impact on the industry through innovative products, creative expertise and unparalleled customer experiences.

Today, we’re shedding some light on the most commonplace workshop essential, and why you can now ditch it for good: the tape measure. For this week’s company highlight, we’re featuring TigerStop: a company that has revolutionized the woodworking industry (as well as many others!) for 28 years with their innovative automated machinery, the SawGear.

Easily the most expensive item in the modern woodworker’s toolkit is the tape measure. The experts at TigerStop have done the math – so before you disagree, just think about it: a manual tape measure leaves room for mistakes. And mistakes cost time, money and valuable resources. So long gone are the days of “measure twice, cut once” – time spent carefully measuring and marking material is valuable time that could instead be spent accomplishing more rewarding tasks.

Here’s where your old-fashioned tape measure is probably hurting you:

Time spent reworking.

Time costs money. If a worker is spending their time fixing prior mistakes when they could be tackling new projects, then it’s possible that your shop’s workflow is not as efficient as it could be. The average worker could be spending up to six hours out of their workday on measuring alone, causing some serious productivity issues.

Scraps and wasted materials.

Particularly as is the case during the pandemic, raw material costs are rising (up 200%!) and wasted supplies are money down the drain, no way around it. According to TigerStop, “studies suggest that for every 100 parts cut, between 2 and 6 are miscut.” So take a hard look at your workshop’s scrap bucket and ask yourself – how much are you losing on mistakes that could’ve easily been avoided?

So, what’s the solution? An automated positioner is three times more productive than the ordinary manual tape measure. An automated stop gauge cuts parts perfectly every time, and streamlines your efforts by reducing the time spent fixing mistakes – helping to in turn reduce material costs and waste as a result. These innovative features allow you to cut more material in a work day, and ultimately substantially reduce labor and material costs.

The best part? It’s so easy to use! Absolutely no previous knowledge or expertise is required to successfully operate the SawGear. Even an entry-level operator can be trained within minutes.

According to TigerStop’s Marketing Director and SawGear expert Elizabeth Dick, “Zero knowledge is needed to run these machines. If you can use a cell phone, you can use a TigerStop. There is a crisis going on in manufacturing called the skilled labor gap. There are not enough skilled workers entering manufacturing. Our machinery helps counteract this crisis because an operator with zero training can use our equipment in less than five minutes.”

So to recap, here’s why SawGear’s innovative technology can help you finally ditch that tape measure (and save money!):

- Streamlines workflow – smaller workshops can now easily compete with larger competitors

- Productivity – increases the productivity from your tool 3-4X, small shops can produce more with less employees

- Saves you money – with rising material costs, the SawGear can help you ensure that you get maximum yield out of your material.

- Fewer mistakes – saves you time, no more reworking

- It’s super affordable – in fact, it saves you so much money in the long run, you really can’t afford not to have it.

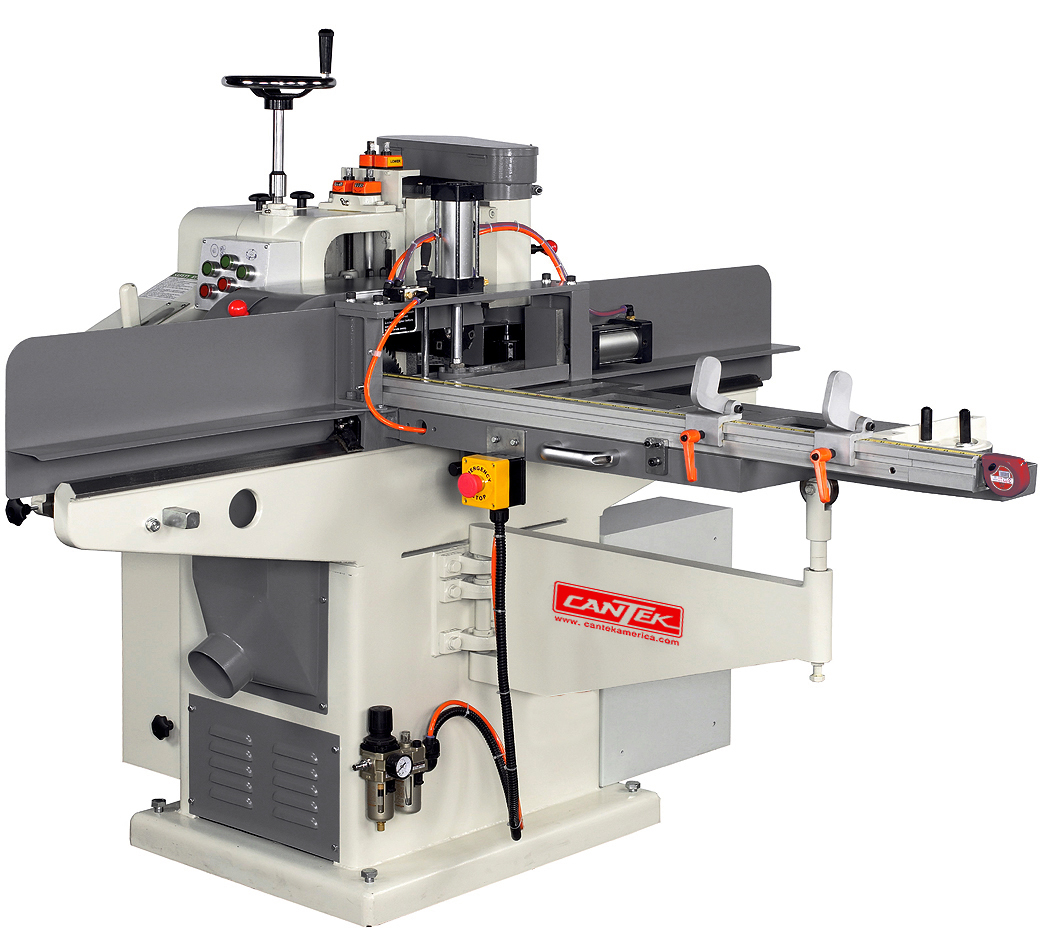

- Easily attach the tools you already own, making them fast, accurate and automated – getting full productivity out of your existing equipment. Adapts to chop saws, upcut saws, vertical panel saws, double miter saws, ironworkers, drills & more.

- Portable – Compact and lightweight, the SawGear can be taken from workshop to jobsite with ease.

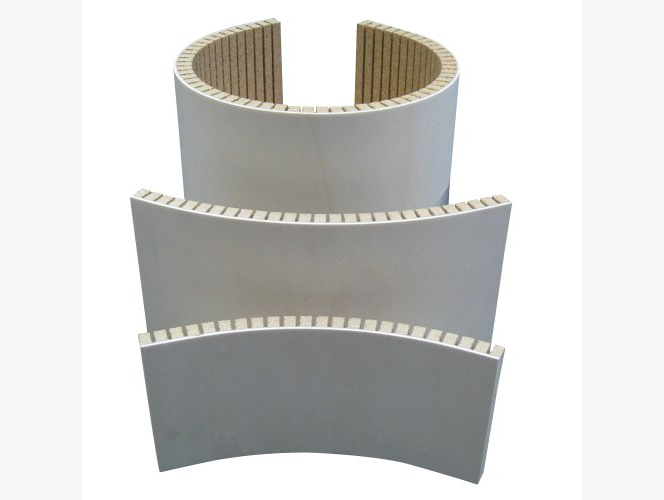

- Versatile – The sky is the limit with what you can create, from beehives and wine barrels, to reclaimed furniture.

- Cut list functionality allows you to program cut lists

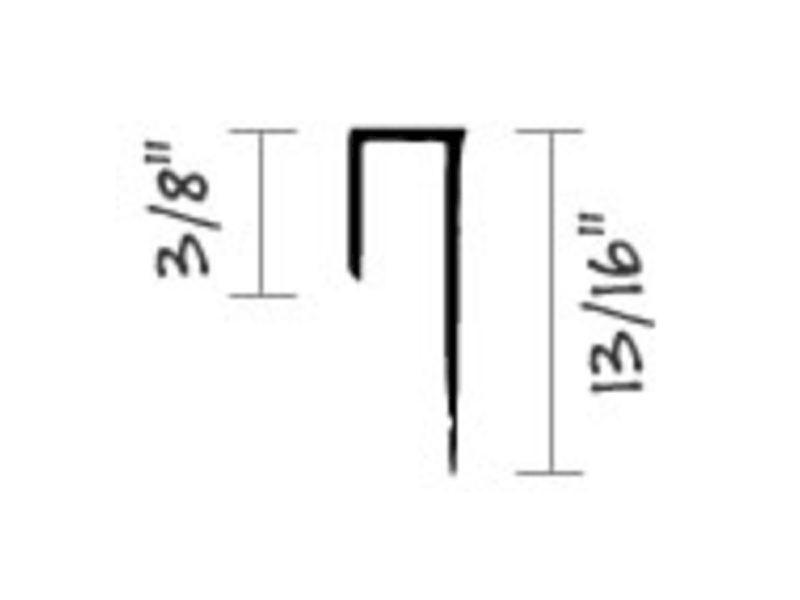

- Accurate to +/-.008″ and repeatable, unlike your tape measure

- Quickly converts fractions to decimals so you don’t have to worry about dealing with difficult measurements like 9/64

- Can be used in metric as well!

Still not convinced? TigerStop has calculated that using the SawGear can save your business roughly $36K per year per worker – just in labor time alone! Check out this article from TigerStop to see the breakdown.

For a limited time, save [pays to wait promo] on the SawGear solution when you preorder between [insert dates here]. Ready to learn more? Check out the SawGear here for yourself, or contact a Wurth Specialist at (800) 422-4389.

Interested in learning more about what TigerStop has to offer? They’re there for you. Check out some of their resources!

Product Overview

SawGear overview & features:

Attachable tools:

Reducing Scrap Material:

Reviews:

https://www.tigerstop.com/blog/category/case-studies-testimonials/

Notable professionals that use SawGear:

Gary Katz from This is Carpentry: https://www.thisiscarpentry.com/2014/09/05/sawgear-a-second-look/

Ethan Abramson: https://www.instagram.com/p/CLuozTMjHQy/

Archways and Ceilings: https://www.instagram.com/p/CQOPKs3D6Q3/

NS Builders: https://www.instagram.com/p/By7i-h3A8Iy/

Generation Builders: https://www.instagram.com/p/BxVcVWgggQJ/

Project examples:

Beehives: https://www.tigerstop.com/blog/precision-automation-makes-production-process-smooth-as-honey/

Wine Barrels: https://www.tigerstop.com/blog/tonnellerie-o-wine-barrels-are-cut-saw-above-the-rest/

Reclaimed Furniture: https://www.tigerstop.com/blog/lamon-luthers-reclaimed-wood-furniture-helps-homeless-reclaim-lives/

Crate Manufacturing: https://www.tigerstop.com/blog/transpak-thinks-outside-the-box-fully-automated-saw-system/

Additional Software Resources:

Product Configurator Tool: https://www.tigerstop.com/build-your-own/

ROI Calculator: https://www.tigerstop.com/roi-calculator

Spare Parts: https://shop.tigerstop.com/

Warranty Info:

Troubleshooting & Customer Service: