-

Metalworking Machinery

brake, roll and shear combination machines (3 products)

brake, roll and shear combination machines (3 products) press brakes (15 products)

press brakes (15 products) sheet metal brakes (30 products)

sheet metal brakes (30 products) sheet metal shears (22 products)

sheet metal shears (22 products) slip & plate rolls (14 products)

slip & plate rolls (14 products) combination mill drill lathe (1 products)

combination mill drill lathe (1 products) drill presses (31 products)

drill presses (31 products) mill drills (6 products)

mill drills (6 products) metal lathes (57 products)

metal lathes (57 products) radial drills (2 products)

radial drills (2 products) drill, mill, and lathe accessories (2 products)

drill, mill, and lathe accessories (2 products) air filtration (1 products)

air filtration (1 products) metalworking dust collection (6 products)

metalworking dust collection (6 products) bead rollers (3 products)

bead rollers (3 products) lockformer (1 products)

lockformer (1 products) power hammers and english wheels (2 products)

power hammers and english wheels (2 products) shrinker/stretchers (2 products)

shrinker/stretchers (2 products) forming and shaping tooling and accessories (1 products)

forming and shaping tooling and accessories (1 products) beveling and deburring (2 products)

beveling and deburring (2 products) finishing (8 products)

finishing (8 products) grinding (17 products)

grinding (17 products) grinding and finishing accessories (3 products)

grinding and finishing accessories (3 products) ironworkers and punches (43 products)

ironworkers and punches (43 products) notchers (22 products)

notchers (22 products) plasma cutters (5 products)

plasma cutters (5 products) plasma tables (4 products)

plasma tables (4 products) hydraulic presses (5 products)

hydraulic presses (5 products) c-frame presses (2 products)

c-frame presses (2 products) h-frame presses (2 products)

h-frame presses (2 products) shop and air presses (7 products)

shop and air presses (7 products)

metalworking abrasive saws (1 products)

metalworking abrasive saws (1 products) metalworking cold saws (11 products)

metalworking cold saws (11 products) metalworking horizontal bandsaw (53 products)

metalworking horizontal bandsaw (53 products) metalworking vertical bandsaw (14 products)

metalworking vertical bandsaw (14 products) saw blades, discs & accessories (1 products)

saw blades, discs & accessories (1 products) strut cutters kits (1 products)

strut cutters kits (1 products) exhaust and hydraulic benders (2 products)

exhaust and hydraulic benders (2 products) mandrel benders (1 products)

mandrel benders (1 products) roll benders (10 products)

roll benders (10 products) rotary draw benders (11 products)

rotary draw benders (11 products) water jets (1 products)

water jets (1 products) wilton shears (1 products)

wilton shears (1 products) -

Woodworking Machinery

- Air Compressors

- Clamps

- CNC Routers

- Combination Machines

- Dovetail Machines

- Downdraft tables

- Drawer Notcher

- Drill Presses

- Drilling, Doweling and Boring

- Dust Collectors and Air Filtration Systems

- Edgebanders

- End Matchers

- Faceframe Tables

- Hydraulic Scissor Lifts

- Jointers

- Lathes

- LED Worklights

- Material Handling Systems

- Measuring Systems

- Molders

- Mortisers

- Planers

- Power Feeders

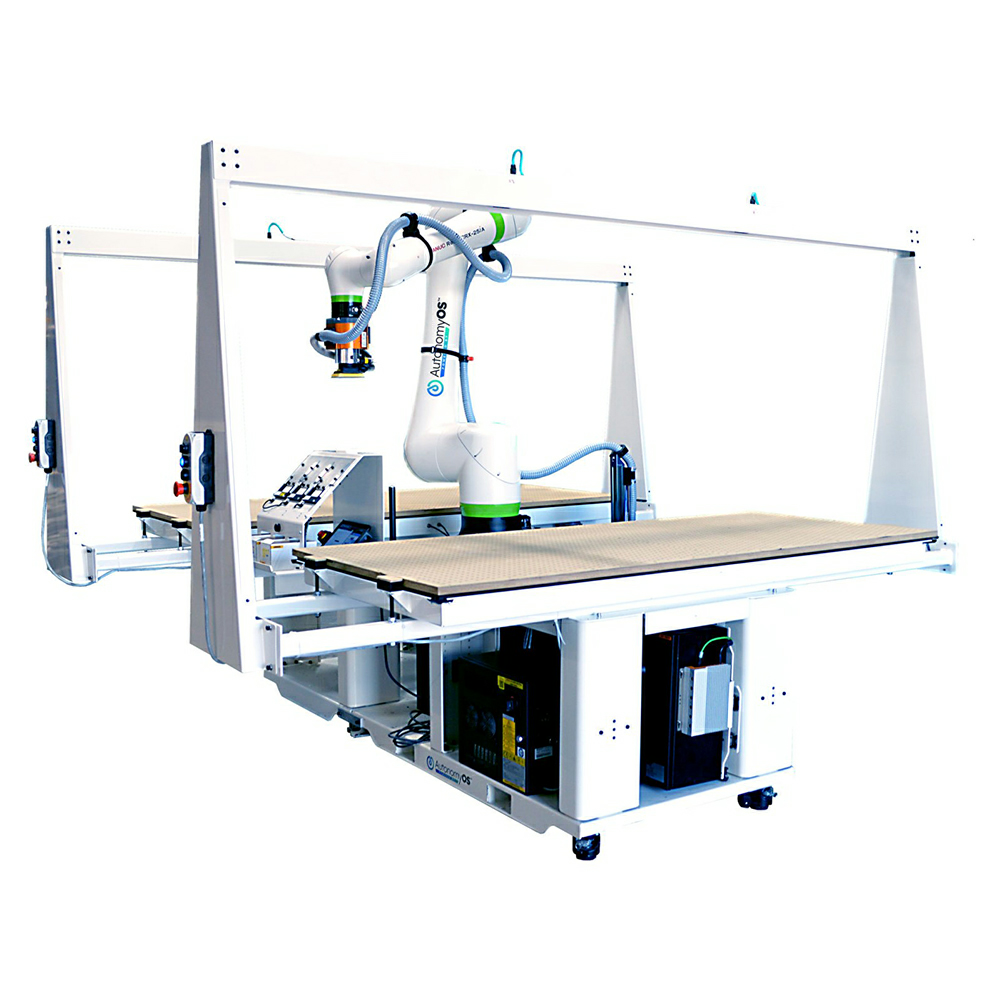

- Robotics & Automation

- Sanders

- Saws

- Semi-automatic Glue and Dowel Machines

- Shapers

- Spray Machines

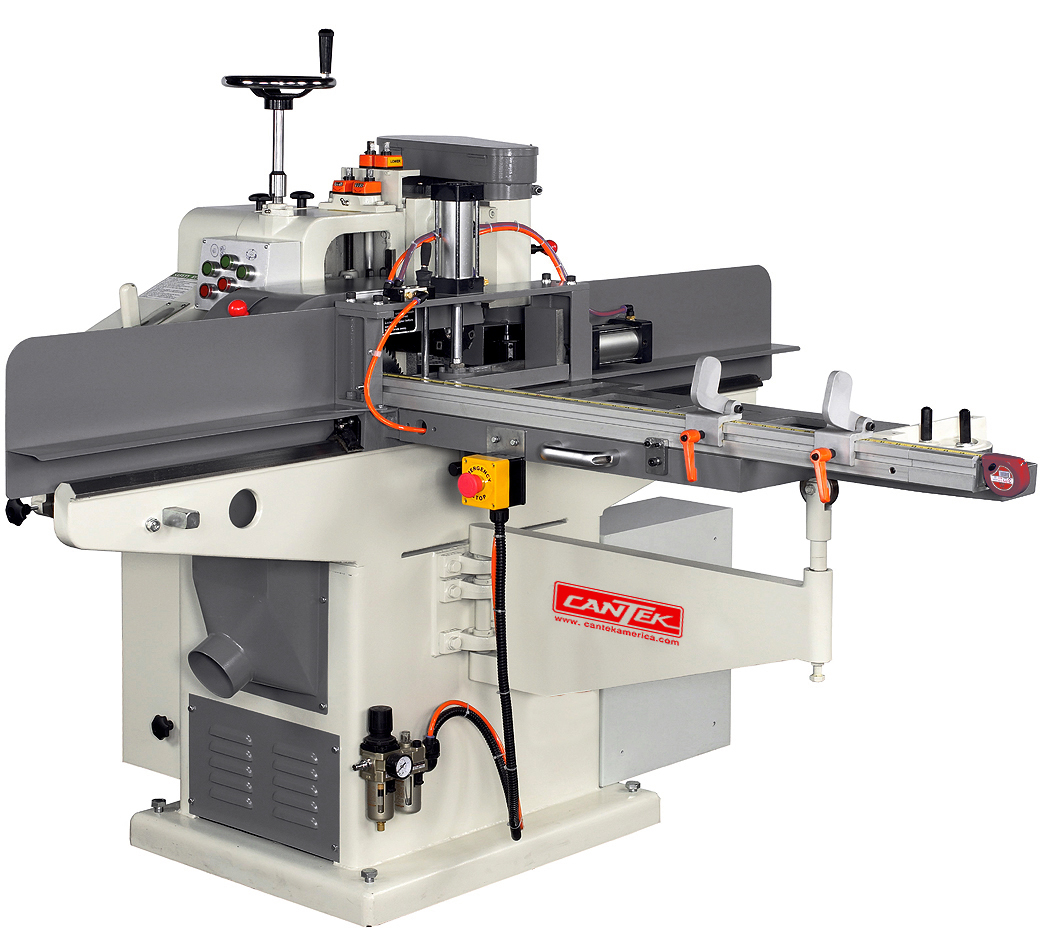

- Tenoners

air compressors (13 products)

air compressors (13 products) air compressor accessories (4 products)

air compressor accessories (4 products) clamps (44 products)

clamps (44 products) combination machines (4 products)

combination machines (4 products) dovetail machines (4 products)

dovetail machines (4 products) drawer notcher (3 products)

drawer notcher (3 products) drill presses (9 products)

drill presses (9 products) drilling, doweling and boring (288 products)

drilling, doweling and boring (288 products) boring machines (14 products)

boring machines (14 products)

hinge boring machines (241 products)

hinge boring machines (241 products) dust collectors and air filtration systems (323 products)

dust collectors and air filtration systems (323 products) down draft sanding tables (48 products)

down draft sanding tables (48 products) dust collectors (228 products)jpw industries air filtration systems (2 products)

dust collectors (228 products)jpw industries air filtration systems (2 products) edgebanders (45 products)

edgebanders (45 products) end matchers (1 products)

end matchers (1 products) hydraulic scissor lifts (2 products)

hydraulic scissor lifts (2 products) jointers (53 products)

jointers (53 products) lathes (48 products)

lathes (48 products) led worklights (7 products)

led worklights (7 products) material handling systems (80 products)

material handling systems (80 products) molders (4 products)

molders (4 products) mortisers (10 products)

mortisers (10 products) planers (55 products)

planers (55 products) power feeders (56 products)

power feeders (56 products) robotics & automation (1 products)

robotics & automation (1 products) sanders (154 products)combination disc and belt sanders (8 products)

sanders (154 products)combination disc and belt sanders (8 products) disc sanders (2 products)

disc sanders (2 products) drum sanders (29 products)

drum sanders (29 products) edge sanders (17 products)

edge sanders (17 products) sanding tables (21 products)

sanding tables (21 products) spindle sanders (4 products)

spindle sanders (4 products) wide belt sanders (32 products)

wide belt sanders (32 products) bandsaws (54 products)

bandsaws (54 products) cut-off/chop saws (15 products)

cut-off/chop saws (15 products) panel saws (32 products)

panel saws (32 products) radial arm saws (5 products)

radial arm saws (5 products) rip saws (7 products)

rip saws (7 products) sawstop (57 products)

sawstop (57 products) table saws (91 products)

table saws (91 products) tigerstop (118 products)

tigerstop (118 products) vertical saws (26 products)

vertical saws (26 products) semi-automatic glue and dowel machines (7 products)

semi-automatic glue and dowel machines (7 products) shapers (36 products)

shapers (36 products) spray machines (17 products)

spray machines (17 products) spray machine accessories (16 products)

spray machine accessories (16 products) tenoners (1 products)

tenoners (1 products) -

Woodworking and Shop Supplies

- Abrasives

- Adhesives, Caulking & Sealants

- Bathroom Hardware & Accessories

- Catches & Locks

- Decorative Hardware & Wood Components

- Drawer Slides & Systems

- Fasteners & Assembly Fittings

- Finishing Products & Equipment

- Hand Tools & Clamps

- Hinges and Lift Systems

- Kitchen Hardware & Accessories

- Knobs & Pulls

- Laminate, Panels and Edgebanding

- Lighting

- Office & Furniture Hardware

- Power Tools, Air Tools & Accessories

- Shelf & Closet Hardware

- Shop Supplies & Safety Equipment

- Sinks & Faucets

- Tooling

accessories (23 products)

accessories (23 products) backing pads (135 products)

backing pads (135 products) belts (425 products)

belts (425 products) discs (937 products)

discs (937 products) pads & sponges (143 products)

pads & sponges (143 products) rolls (129 products)

rolls (129 products) sheets (222 products)

sheets (222 products) specialty abrasives (230 products)

specialty abrasives (230 products) adhesive guns (15 products)

adhesive guns (15 products) adhesive hoses (21 products)

adhesive hoses (21 products) adhesives (534 products)

adhesives (534 products) caulking & sealants (293 products)

caulking & sealants (293 products) solvents (13 products)

solvents (13 products) spray accessories (15 products)

spray accessories (15 products) wood fillers & putty (175 products)

wood fillers & putty (175 products) bathroom stall hardware (131 products)

bathroom stall hardware (131 products) curling iron & hair dryer holders (14 products)

curling iron & hair dryer holders (14 products) pull out organizers (7 products)

pull out organizers (7 products) racks & towels bars (337 products)

racks & towels bars (337 products) robe hooks (128 products)

robe hooks (128 products) undersink drip trays (4 products)

undersink drip trays (4 products) bar railings (88 products)

bar railings (88 products) block & spools (10 products)

block & spools (10 products) columns (291 products)

columns (291 products) corbels (408 products)

corbels (408 products) decorative fillers & caps (66 products)

decorative fillers & caps (66 products) decorative grills & lattices (45 products)

decorative grills & lattices (45 products) feet (125 products)

feet (125 products) hardwood dowels (4 products)

hardwood dowels (4 products) island turnings (225 products)

island turnings (225 products) moldings (221 products)

moldings (221 products) onlays (18 products)

onlays (18 products) rosettes (2 products)

rosettes (2 products) switch & outlet plates (57 products)

switch & outlet plates (57 products) tag holders (1 products)

tag holders (1 products) drawer box systems (1010 products)

drawer box systems (1010 products) drawer materials (76 products)

drawer materials (76 products) drawer organizers (1 products)

drawer organizers (1 products) drawer slides (1808 products)

drawer slides (1808 products) drawer slides and systems accessories (142 products)

drawer slides and systems accessories (142 products) screws (2309 products)

screws (2309 products) nails (83 products)

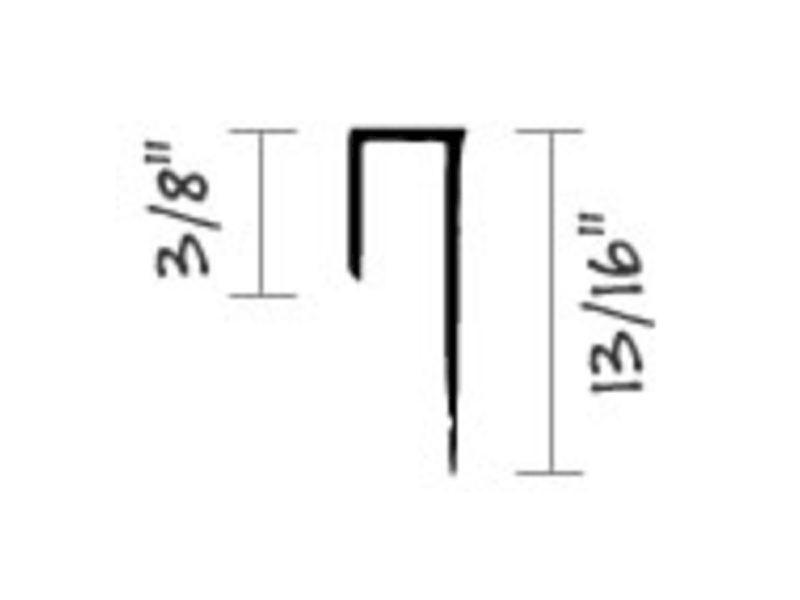

nails (83 products) staples (58 products)

staples (58 products) bed rail fasteners (5 products)

bed rail fasteners (5 products) bolts (7 products)

bolts (7 products) brackets & braces (89 products)

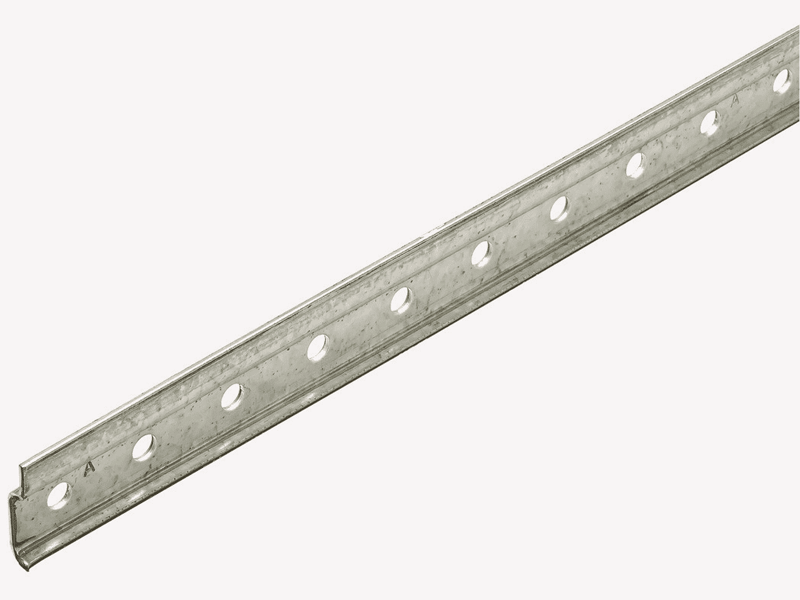

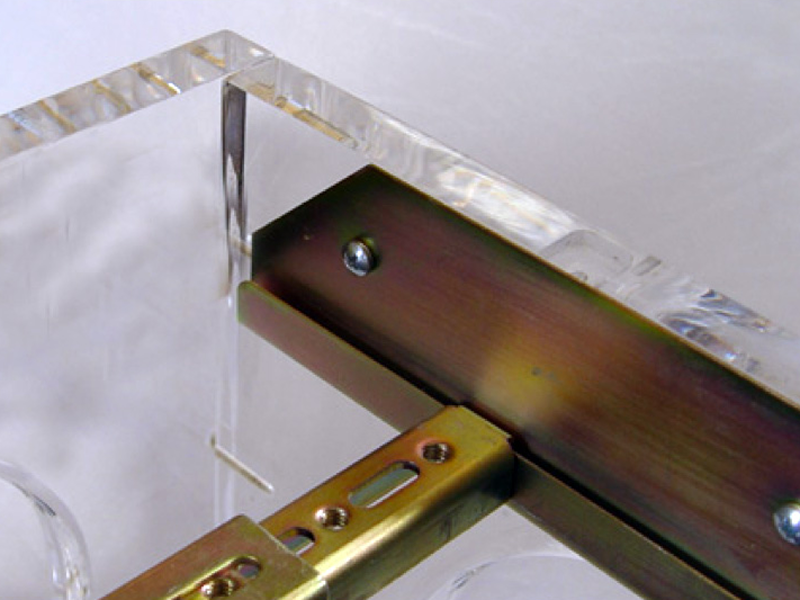

brackets & braces (89 products) cabinet hanging rails (28 products)

cabinet hanging rails (28 products)

countertop connectors (17 products)

countertop connectors (17 products) covercaps (1336 products)

covercaps (1336 products) drywall anchors (7 products)

drywall anchors (7 products) fastener organizers (1 products)

fastener organizers (1 products) grill & glass clips (18 products)

grill & glass clips (18 products) joining biscuits & tenons (102 products)

joining biscuits & tenons (102 products) panel fastening clips (62 products)

panel fastening clips (62 products) plastic dowels & screws for dowels (27 products)

plastic dowels & screws for dowels (27 products) raised panel spacers (36 products)

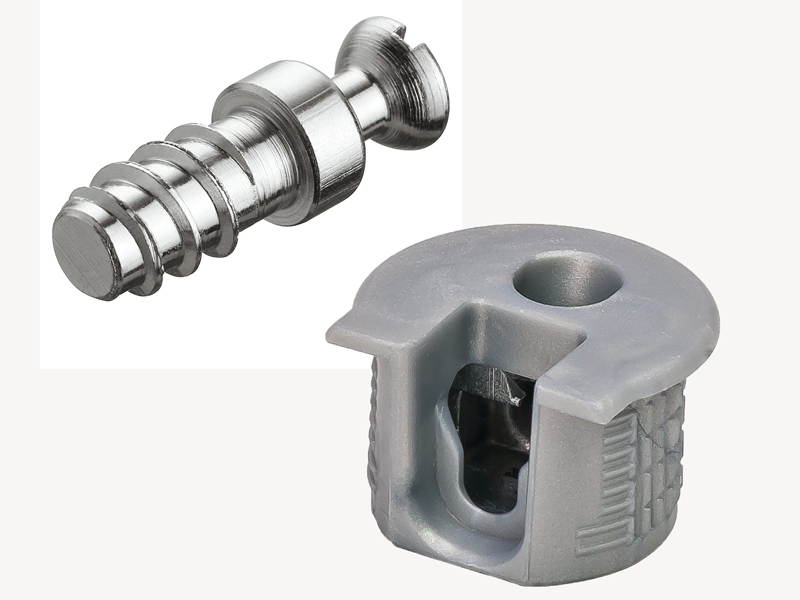

raised panel spacers (36 products) rta fittings (84 products)

rta fittings (84 products) washers (42 products)

washers (42 products) wood dowel pins & rods (47 products)

wood dowel pins & rods (47 products) wood hole plugs (13 products)

wood hole plugs (13 products) chemcraft systems (557 products)

chemcraft systems (557 products) finishes (196 products)

finishes (196 products) glazes (14 products)

glazes (14 products) solvents (190 products)

solvents (190 products) spray systems (497 products)

spray systems (497 products) wood sealers (83 products)

wood sealers (83 products) alignment tools (6 products)

alignment tools (6 products) allen keys (17 products)

allen keys (17 products) chisels, knives & scrapers (28 products)

chisels, knives & scrapers (28 products) clamps (111 products)

clamps (111 products) edge sanding tools (2 products)

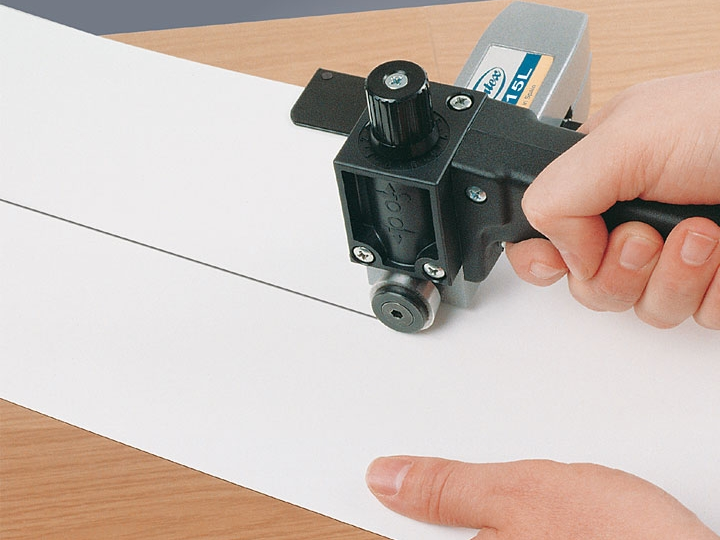

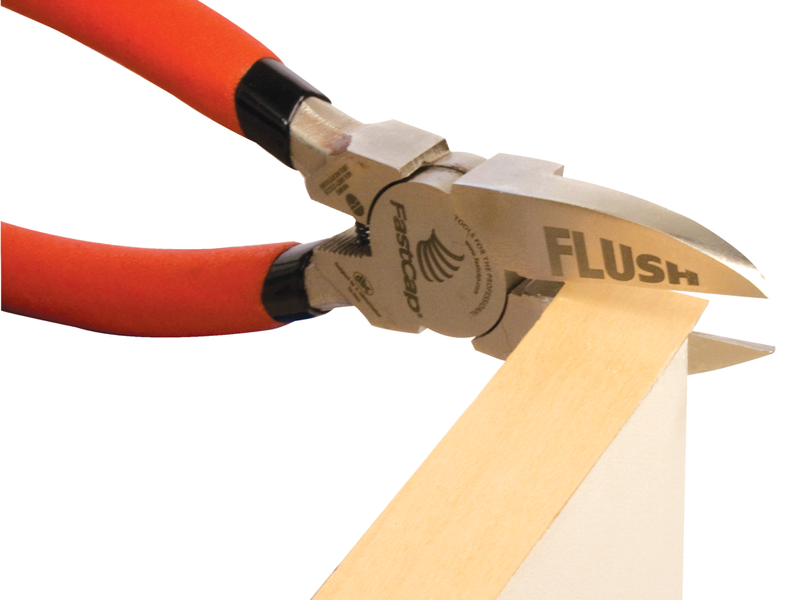

edge sanding tools (2 products) edgebanding & veneer trimmers (13 products)

edgebanding & veneer trimmers (13 products) files & brushes (21 products)

files & brushes (21 products) hammers & mallets (3 products)

hammers & mallets (3 products) hand saws (1 products)

hand saws (1 products) hand tool accessories (33 products)

hand tool accessories (33 products) hanging & assembly tools (2 products)

hanging & assembly tools (2 products) jigs & assembly aids (120 products)

jigs & assembly aids (120 products) pliers & cutters (11 products)

pliers & cutters (11 products) pressure rollers (6 products)

pressure rollers (6 products) ratchets (13 products)

ratchets (13 products) screwdrivers (23 products)

screwdrivers (23 products) seaming tools (2 products)

seaming tools (2 products)

supports (27 products)

supports (27 products) t-handles (41 products)

t-handles (41 products) tape measures (26 products)

tape measures (26 products) wrenches (3 products)

wrenches (3 products) accessories (114 products)

accessories (114 products) euro hinges (1474 products)

euro hinges (1474 products)

hinges (419 products)

hinges (419 products) lifts & lid stays (286 products)

lifts & lid stays (286 products) appliance garages (53 products)

appliance garages (53 products) appliance lifts (8 products)

appliance lifts (8 products) blind corner units (265 products)

blind corner units (265 products) bread drawers (5 products)

bread drawers (5 products) cabinet accessories (5 products)

cabinet accessories (5 products) cabinets (107 products)

cabinets (107 products) cutlery trays & drawer inserts (235 products)

cutlery trays & drawer inserts (235 products) cutting boards & knife blocks (33 products)

cutting boards & knife blocks (33 products) door storage (50 products)

door storage (50 products) lazy susans (578 products)

lazy susans (578 products) maple butcher blocks & backsplashes (21 products)

maple butcher blocks & backsplashes (21 products) pantry units (32 products)

pantry units (32 products) plate racks (25 products)

plate racks (25 products) pull down shelves (76 products)

pull down shelves (76 products) pull out units (1105 products)

pull out units (1105 products) range hoods (396 products)

range hoods (396 products) sink front trays & hinges (177 products)

sink front trays & hinges (177 products) sink setters (2 products)

sink setters (2 products) spice racks & trays (65 products)

spice racks & trays (65 products) tambour door systems (169 products)

tambour door systems (169 products) trash, waste and recycling (451 products)

trash, waste and recycling (451 products) tray dividers (47 products)

tray dividers (47 products) undersink drip trays (17 products)

undersink drip trays (17 products) wine and stemware racks (179 products)

wine and stemware racks (179 products) aluminum moldings & braces (23 products)

aluminum moldings & braces (23 products) backing sheets (32 products)

backing sheets (32 products) dry erase & tackable boards (7 products)

dry erase & tackable boards (7 products) edge treatments (126 products)

edge treatments (126 products) edgebanding (1376 products)

edgebanding (1376 products) laminates & solid surface panels (9474 products)

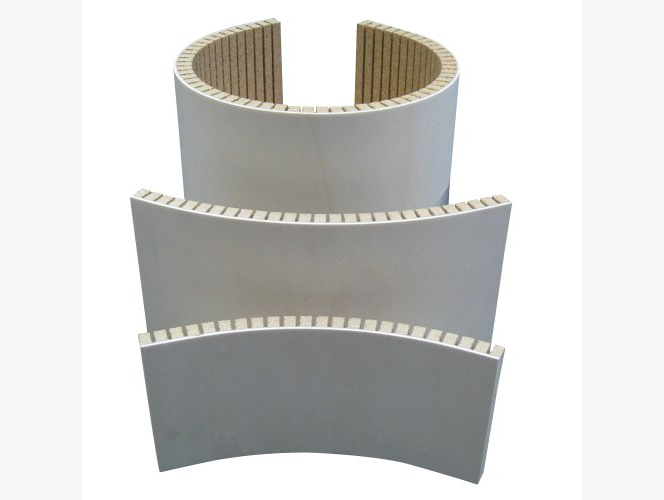

laminates & solid surface panels (9474 products) lightweight panels & bendable boards (159 products)

lightweight panels & bendable boards (159 products) veneers sheets (159 products)

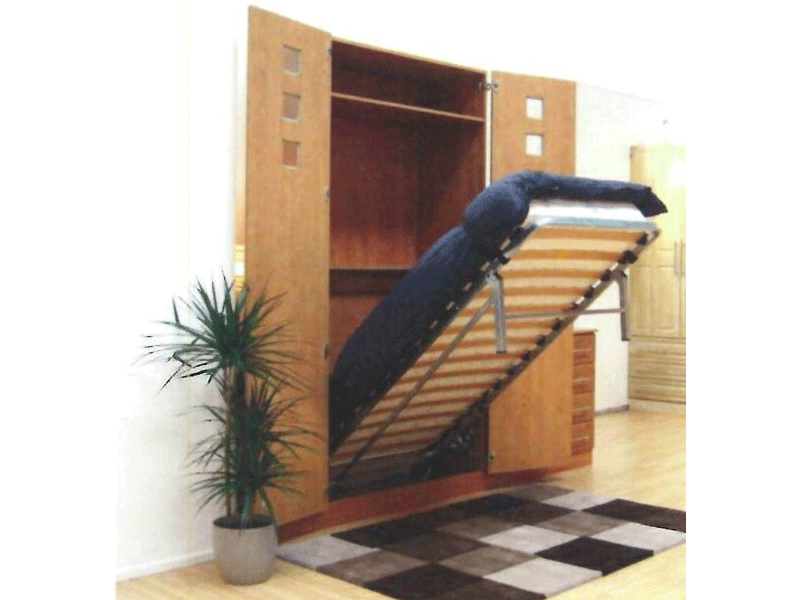

veneers sheets (159 products) bed mechanisms (12 products)

bed mechanisms (12 products) cpu holders (10 products)

cpu holders (10 products) electric trim rings (13 products)

electric trim rings (13 products) grommets & wire management (644 products)

grommets & wire management (644 products) keyboard arms & trays (13 products)

keyboard arms & trays (13 products) leg levelers, casters & glides (445 products)

leg levelers, casters & glides (445 products) pencil drawer trays & slides (1 products)

pencil drawer trays & slides (1 products) swivels (9 products)

swivels (9 products) table & furniture legs (363 products)

table & furniture legs (363 products) toe kicks (26 products)

toe kicks (26 products) accessories for power & air tools (230 products)

accessories for power & air tools (230 products) air hoses (20 products)

air hoses (20 products) air line accessories (15 products)

air line accessories (15 products) belt sanders (4 products)

belt sanders (4 products) combo kits (8 products)

combo kits (8 products) drills & drivers (27 products)

drills & drivers (27 products) edgebanders, heat guns & hand irons (5 products)

edgebanders, heat guns & hand irons (5 products) hand sanders (113 products)

hand sanders (113 products) laminate trimmers (1 products)

laminate trimmers (1 products) planers (6 products)

planers (6 products) plate & tenon joiners (2 products)

plate & tenon joiners (2 products) portable dust extractors (58 products)

portable dust extractors (58 products) router accessories (70 products)

router accessories (70 products) routers (15 products)

routers (15 products) saws (34 products)

saws (34 products) staplers & nailers (20 products)

staplers & nailers (20 products) closet mirrors (5 products)

closet mirrors (5 products) closet rods, pull down (30 products)

closet rods, pull down (30 products) closet rods, standard (232 products)

closet rods, standard (232 products) closet rods, valet (47 products)

closet rods, valet (47 products) glass shelf hardware (22 products)

glass shelf hardware (22 products) hampers & closet baskets (233 products)

hampers & closet baskets (233 products) hooks & racks (257 products)

hooks & racks (257 products) ironing boards (72 products)

ironing boards (72 products) jewelry trays & liners (34 products)

jewelry trays & liners (34 products) library ladders (380 products)

library ladders (380 products) pant racks (68 products)

pant racks (68 products) pilasters (119 products)

pilasters (119 products) retail display components (1 products)

retail display components (1 products) shelf braces & brackets (440 products)

shelf braces & brackets (440 products) shelf pins & supports (235 products)

shelf pins & supports (235 products) shelves (74 products)

shelves (74 products) shoe storage (33 products)

shoe storage (33 products) slatwall brackets (33 products)

slatwall brackets (33 products) sliding door hardware (566 products)

sliding door hardware (566 products) standards & brackets (397 products)

standards & brackets (397 products) tie, belt & scarf racks (79 products)

tie, belt & scarf racks (79 products) utility hooks (8 products)

utility hooks (8 products) aprons (8 products)

aprons (8 products) back supports (3 products)

back supports (3 products) batteries (9 products)

batteries (9 products)

brooms (8 products)

brooms (8 products) brushes & paint supplies (37 products)

brushes & paint supplies (37 products) caps (1 products)

caps (1 products) cleaners (26 products)

cleaners (26 products) drink coolers, beverages & supplies (24 products)

drink coolers, beverages & supplies (24 products) empty bottles, lids & cans (61 products)

empty bottles, lids & cans (61 products) eye protection (48 products)

eye protection (48 products) fans (3 products)

fans (3 products) fire extinguishers (6 products)

fire extinguishers (6 products) first aid & emergency equipment (14 products)

first aid & emergency equipment (14 products) gloves (102 products)

gloves (102 products) hearing protection (16 products)

hearing protection (16 products) janitorial & sanitation supplies (31 products)

janitorial & sanitation supplies (31 products) knee pads (1 products)

knee pads (1 products) literature (1 products)

literature (1 products) lubricants (21 products)

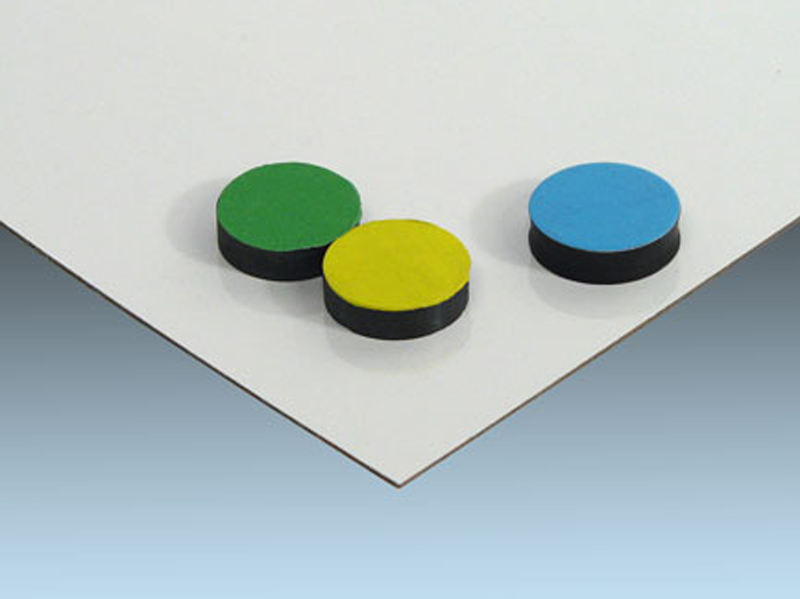

lubricants (21 products) magnets (3 products)

magnets (3 products) packing & shipping supplies (23 products)

packing & shipping supplies (23 products) paint & glue rollers (11 products)

paint & glue rollers (11 products) power cords & shop lighting (24 products)

power cords & shop lighting (24 products) respiratory protection (78 products)

respiratory protection (78 products) safety cloths (36 products)

safety cloths (36 products) shims (8 products)

shims (8 products) shop carts & dollies (24 products)

shop carts & dollies (24 products) shop rags & blankets (22 products)

shop rags & blankets (22 products) signs (4 products)

signs (4 products) step stools (4 products)

step stools (4 products) tapes (82 products)

tapes (82 products) temperature indicating liquids (3 products)

temperature indicating liquids (3 products) tool bags (8 products)

tool bags (8 products) velcro (4 products)

velcro (4 products) writing & marking supplies (6 products)

writing & marking supplies (6 products) accessories for sinks (96 products)

accessories for sinks (96 products) acrylic sinks (73 products)

acrylic sinks (73 products)

edge sinks (7 products)

edge sinks (7 products) faucets (73 products)

faucets (73 products) quartz sinks (331 products)

quartz sinks (331 products) stainless steel sinks (117 products)

stainless steel sinks (117 products) drill bits (693 products)

drill bits (693 products) driver bits (400 products)

driver bits (400 products) hole saws (15 products)

hole saws (15 products) insert knives (104 products)

insert knives (104 products) planer blades (15 products)

planer blades (15 products) plug cutters (9 products)

plug cutters (9 products) replacement blades (10 products)

replacement blades (10 products) router bits (2629 products)

router bits (2629 products) saw blades (416 products)

saw blades (416 products) -

Quick Order

Quick Order List✕Input your items below (or) upload in bulk from a .csv file.